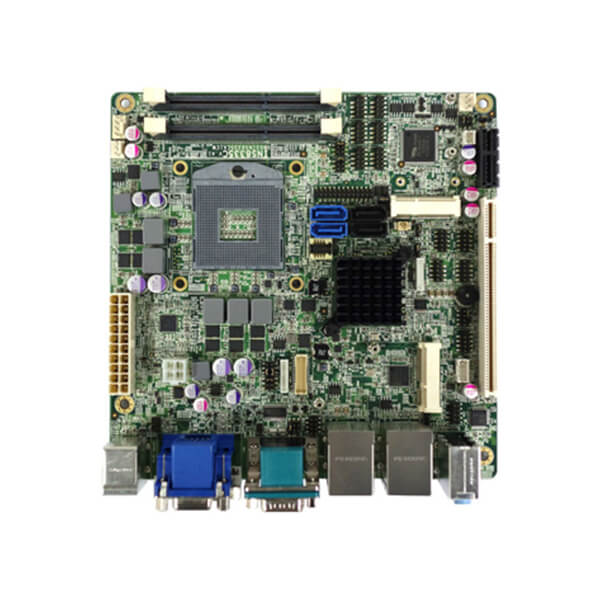

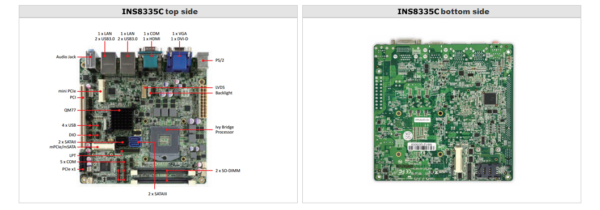

Description

Intel® Ivy Bridge QM77 Mini-ITX Industrial MB, Wide Temp. -20 to 70°C (-40 to 85°C optional)

- Intel® 22nm Ivy Bridge Processor (Mobile)(rPGA988)

- 2 x DDR3 SO-DIMM up to 16 GB

- Muliti-display: VGA, DVI-D, LVDS, HDMI

- 1 x PCI, 1 x PCIe x1, 2 x Mini PCIe, 1 x mSATA

- 4 x SATA (2 x SATAIII, 2 x SATAII)

- 8 x USB ports (4 x USB 3.0, 4 x USB 2.0)

- 6 x COM ports

- 16-bit DIO (8 in/8 out)

- Wide operating temp. -20 to 70°C (-40 to 85°C optional)

INS8335C is a Mini-ITX form factor industrial motherboard, powered by Intel® Ivy Bridge 22nm processor and QM77 chipset. Processor i7-3610QE plus Intel® QM77 chipset consumes only 45W and 4.1W individually. It supports four-core that can turbo up to eight-core. CPU co Extreme computing power and reliability are guaranteed by this powerful combination. Clock speed can boost from 2.3 GHz to 3.3 GHz. ATX power supply unit provides two connectors for the motherboard: a 4-pin auxiliary connector providing additional power to the CPU and a main 24-pin power supply connector. Wide range 9V~24V DC input design can protect the board from damages caused by sudden surge of voltage, thus further secure the reliability. Extended temperature operation from -40 to +85°C ensures unbeatable reliability. Fast processor equips with rich legacy I/O features such as: 6 COM ports (3 by RS485/232/422); 16 Bit DIO; LPT; PS2. The expansion capacity of INS8335C is stunning, it supports 1 x PCI, 1 x PCI_e, 1 x mPCI_e, and 1 x mSATA. A set of PS/2 connectors is specially installed for convenient keyboard & mouse usage. With various extensive ability and strong computing power, INS8335C is a key solution for industrial automation such as drilling machines, drilling rigs, and CNC machine applications.

Integrated thermal solution – the incorporation of four pure copper heat pipes and an copper heat sink

INS8335C, with its dynamic 4-core 45W core i7-3610QE processor, demands an equal high level thermal solution. To achieve maximum heat dissipation, the design and implementation of heat pipes is the golden key. In this case, a copper heat sink and passively cooled enclosure is implemented to establish an effective dissipation environment. The structure of four pure copper heat pipes is to ensure supreme thermal efficiency. The heat pipes are capable of prompt dissipation of the heat generated by the CPU’s inner core while it’s computing. According to Perfectron’s testing result, each pure copper heat pipe has the ability to dissipate 9w of heat. The combination of four heat pipes pushes the dissipation ability to a new level. Our tailor-made, precision-aimed integral structural heat sink and embedded heat pipes constitute an excellent fanless thermal solution. When the CPU hits 100% full potency, the implementation of four 6mm (minimum) pure copper heat pipes can keep it running at full speed – 2.3 Ghz!

Effective cooling devices for maximum heat dissipation

Perfectron’s unique heat sink and heat pipe are designed with precision. Each of the key heat-dissipating components is tailor-made in accordance with different interior and exterior structure. Unlike traditional solutions that utilize aluminum as the dissipating media for CPU and fin. We insist on incorporating 99% pure copper heat spreader, which is eight times higher in density than aluminum. Our tailor-made pure copper heat spreader is treated with the most precise CNC technology, cutting four 6.1mm wide track so that the 6mm wide heat pipes can fit seamlessly. Compared with conventional solid heat conductors, such as aluminum, copper, granite, and graphite, of which thermal conductivity ranges from only 250 W/m•K to 1,500 W/m•K, Perfectorn’s effective heat pipe design, with impressively high thermal conductivity (5000 W/m•K to 200000 W/m•K) that is 40 times higher than standard aluminum, is guaranteed to charge the system to the maximum turbo speed with minimum overall impact.