Description

Mini ITX form factor, Intel® Cedarview D2550 CPU on board, Extended Temperature. -40 to 85°C

- Intel® Cedarview D2550 CPU + Intel® NM10

- Single/Dual channel 18/24-bit LVDS

- Rich I/O interface with 10 COM, 7 USB, 2 LAN

- Flexible expansion with 1 x mPCIe

- 16bit DIO (8 in/8 out)

- 9 ~24V wide voltage DC-in design

- Extended operating temperature. -40 to 85°C

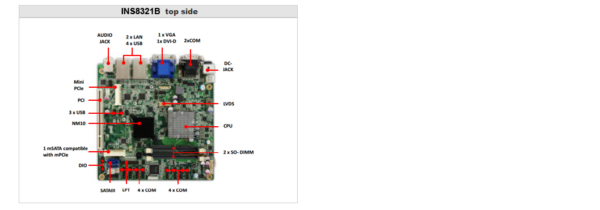

INS8321B is a Mini-ITX form factor industrial motherboard, designed with Intel® Cedarview D2550 CPU soldered onboard. Processor D2550 supports dual core 1.86 GHz, presenting only 10W extremely low power consumption with high performance. With processor soldered onboard can significantly enhance the resistance of vibration and shock. Extensive I/O interface with 10 COM ports and 16 bit DIO can increase a variety of possibility for device connect ability. Extended temperature operation from -40 to +85°C ensures unbeatable reliability and wide range DC-in 9 ~24V design can protect the board from damages caused by sudden surge of voltage. INS8321B is rugged SBC and expected to be a good solution for automation and transportation industry.

Thermal solution for fanless system– the incorporation of two pure copper heat pipes and aluminum heat sink

Thermal design is the solution for the maximum reduction of heat. With upper passive aluminum heat sink and cooled aluminum enclosure is implemented to create an effective dissipation environment. With two pure high efficiency copper heat pipes plus aluminum heat sink to ensure maximum thermal efficiency. Copper vacuum Heat-Pipe has effective thermal conductivities that range from 5,000 W/m•K to 200,000 W/m•K to effectively transfer heat from the heat source to the heat sink. This advanced thermal solution enables system to operate smoothly under temperature range -40 to 80°C -without processor throttling.

Effective cooling solution for maximum heat dissipation

Perfectron implements unique cooling solution with the copper heat spreader and aluminum heat sink. To adopt the physical property of copper and aluminum, the copper heat spreader touches the heat source – processor and chipset and absorbs the heat rapidly, heat is then transferred to upper aluminum heat sink; the aluminum heat sink dissipates the heat into surrounding air promptly. The heat sink design with high and low shape to create temperature difference then produce airflow, the wave lines on the lateral side of heat sink can increase the dissipating interface up to 30 to 40%. Through above unique design could achieve maximum heat dissipation.