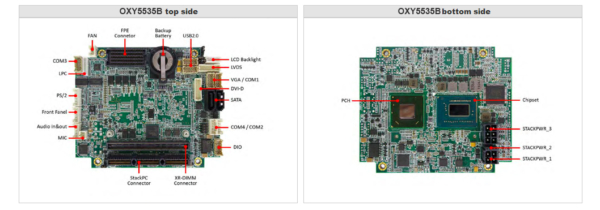

Description

Intel® Ivy Bridge Core™ i7 StackPC (PCIe/104) with QM77 Chipset, Extended Temperature. -40 to 85°C

- Supports Intel® Ivy Bridge CPU onboard

- StackPC-FPE CPU module, next generation of PCIe/104

- 1 x StackPC, 1 x FPE

- Supports 1 x PCIe_16, 1 x PCIe_4, 4 x PCIe, 4 x USB, 2 x GbE

- VGA, DVI-D, 24-bit LVDS

- Onboard SATA NAND Drive up to 32 GB (MLC)

- Rugged XR-DIMM DDR3 1600 support up to 8GB w/ECC

- 12V DC-in

- Extended operation temp. -40 to 85°

Introduction

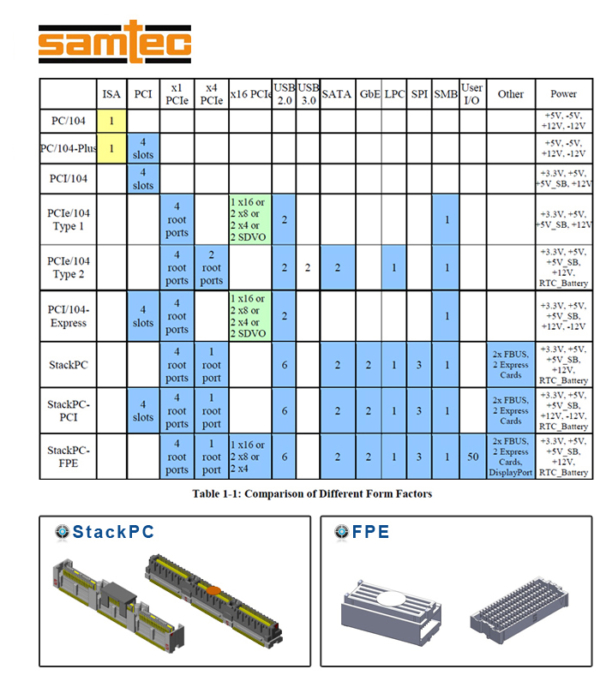

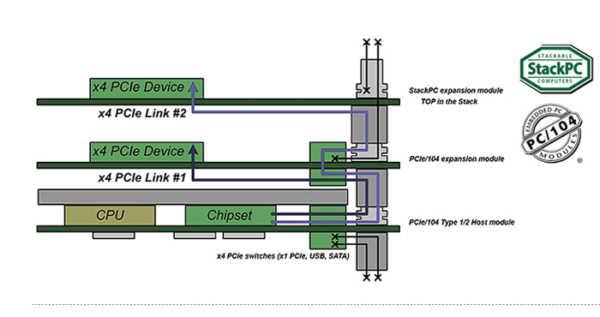

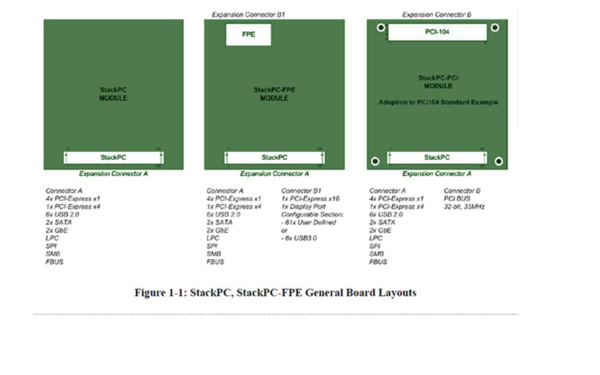

StackPC is the new standard of embedded stackable system design, the OXY5535B presents the new approach to stackable system design and development. The main competitive distinction of the StackPC connector is the combination of most popular low speed interfaces such as USB, COM, CAN, SPI, LPC and high speed SATA, Gigabit Ethernet and PCI-Express x1, x4 within one stack expansion connector. This combination allows to minimize the number of wired connections inside the stack system enclosure and gives more design and manufacturing flexibility. The StackPC modules are much easier to be designed due to the consistent stack up systems development only. This approach doesn’t require placing high speed and low speed signal switches. The stack direction specifies the mechanical part on host and peripheral modules, which makes them cost-effective as well as easy to design, verify and use. The unified approach to stack power supply and communication interfaces output is aimed to increase the different vendors products’ compatibility.

Benefits of StackPC – Expansion Connector

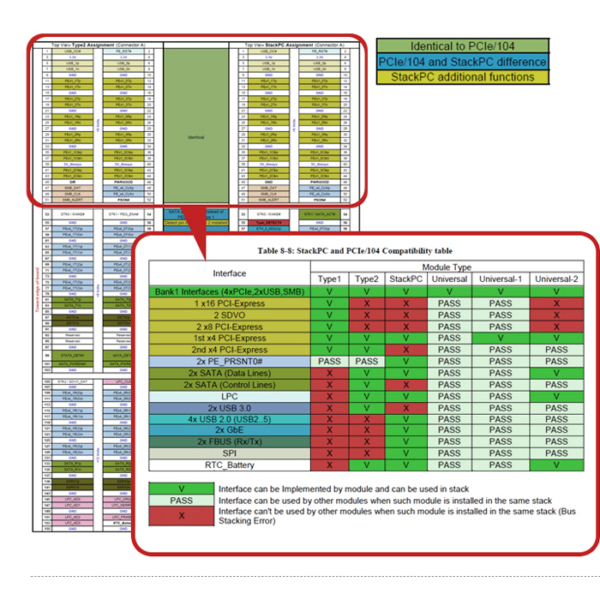

The StackPC Specification defines new approach to stackable systems design and development. The specification includes all valuable heritages of PC/104 standards along with the new features of StackPC connector.

The main competitive distinction of the StackPC connector is the combination of most popular low speed interfaces such as USB, COM, CAN, SPI, LPC and high speed SATA, Gigabit Ethernet and PCI-Express x1, x4 within one stack expansion connector.

The dimension and pin of the StackPC connector is as the same as the PCIe/104 connector.

- Compatibility with PCIe/104

- BANK1 is the same

- PCIe x4 StackPC modules can be placed into PCIe/104 stack on the TOP

- The same protection mechanism as in Type1/Type2

- BANK1 is the same as PCIe/104 Type2

- Universal modules are fully compatible

- Flexibility in adaptation to most popular form factors

- Maximum compatibility with the most popular PCIe/104 modules

- More features with FPE expansion up to PCIe_16

- EPIC SBC Carrier Module SK507

- StackPC-FPE carrier module in EPIC form factor

- 2 x mPCIe

- 1 x VGA, 1 x DP

- 4 x USB3.0

- 2 x GbE

- 2 x RS485

- 1 x SATA, 1 x CFast

| GPU | GT 730M(N14M-GS-B-A1) |

|---|---|

| Bus Type | PCI-Express 3.0/2.0 |

| Nazwa rdzenia | GK210 |

| Proces technologii | 28 nm |

| Rdzenie CUDA | 384 rdzeni |

| Zegar GPU | 719 MHz |

| Ilość pamięci | 1024 MB |

| Typ pamięci | DDR3 |

| Zegar pamięci | 900 MHz |

| Interfejs pamięci | 64-bit |

| Obsługa OS | Win7, Win8 i Linux |

| Obsługa obrazu | Dekoder wideo - H.264, VC1, MPEG2 1080p DP x 4 - do 3840 x 2160 CRT x 1 (13-stykowa głowica) - do 2048 x 1536 |

| Licza wyświetlaczy | 4 (maksymalnie) |

| Obsługiwane technologie | Optimus, GeForce Experence, TXAA, GPU Boost 2.0, PhysX, CUDA, FXAA, OpenCL, Direct Compute, PureVideo HD, HDCP, 3D Vision, OpenGL |

| Informacje o płycie | Wymiary płyty: 95,89 mm x 90,17 mm Kierunek stosu: W GÓRĘ (w jedną stronę) Forma wsparcia: StackPC i PCIe / 104 |

CPU Performance

The OXY5535B offers highly effectively heat conductive and heat convective thermal solutions to meet the demands of customers’ extended temperature requirements. The heat conductive solutions uses an aluminum flat mass to place in direct contact with the processor and chipset, the heat from chips then transfers it to the case of the system. In addition, the convective thermal solutions introduce airflow directed to move across the surface of a fin style heatsink placed on top of the processor and chipset. This can be done with the aid of an appropriately sized fan placed in top of the fin style heatsink. Alternately, enclosure airflow can be routed to flow across a fin style heatsink.

Test Result

| General information | Model | F1-30 | |

|---|---|---|---|

| CPU Type | Intel® 3rd generation Core™ i7 Processor | ||

| System Chipset | Intel® QM77 | ||

| Memory type | 1 x DDR3 1333/1600MHz XR-DIMM 8 GB | ||

| Storage | HDD/SDD support | 1 x 2.5” SSD | |

| 2 x mSATA SSD backup storage | |||

| I/O connectors | Type A (Amphenol D38999 Connectors) | Power button | 1 x Waterproof Button with Backlight |

| DP | 4 | ||

| COM | 4 | ||

| Ethernet | 2 | ||

| USB 2.0 | 2 | ||

| DC-in | 1 | ||

| Type B (Phoenix Contact M12 Connectors) | Power button | 1 x Waterproof Button with Backlight | |

| DP | 4 | ||

| COM | 2 | ||

| Ethernet | 2 | ||

| USB 2.0 | 4 | ||

| DC-in | 1 | ||

| Mechanical | Housing | Aluminum | |

| Weight | 16 Kg (35.24 lb) | ||

| Ingress Protection | IP65 | ||

| Dimension (W x H x D) | 189.5 x 230 x 318 mm | ||

| Power Requirement | Input Voltage | 16.5 to 50 VDC (Compliant with MIL-STD-1275/704/461F/202) |

|

| Environment Limits | Operating temperature | -40 to 75°C (-40 to 158°F) | |

| Storage temperature | -40 to 85°C (-40 to 185°F) *without HDD installed | ||

| Relative Humidity | Up to 95%RH @40°C, non-condensing | ||

| Ingress Protection | Designed for compliance to IP65, MIL-STD-810G | ||

| TEST STANDARD | EMI/EMC | Designed to meet MIL-STD-461F | |

| Military | Designed to meet MIL-STD-810G | ||

| Vibration & Shock | Designed to meet MIL-STD-810G | ||

| Stackable Module | SK210 | Graphic module with NVIDIA730M GPU supports four DP output | |

| SK220 | MXM graphic card carrier supports six miniDP output | ||

| SK303 | COM port module with total four COM ports (RS232/422/485 selectable) | ||

| SK401 | Storage carrier with one 2.5" HDD/SSD socket and two mSATA socket | ||

| SK506 | Ethernet module with total six 10/100/1000 mbps ethernet connections | ||

Test Configuration

| GPU | GT 730M(N14M-GS-B-A1) |

|---|---|

| Bus Type | PCI-Express 3.0/2.0 |

| Core Name | GK210 |

| Process Technology | 28 nm |

| CUDA Cores | 384 cores |

| GPU Clock | 719 MHz |

| Memory Amount | 1024 MB |

| Memory Type | DDR3 |

| Memory Clock | 900 MHz |

| Memory Interface | 64-bit |

| OS Support | Win7, Win8 and Linux |

| Display Support | Video decoder - H.264, VC1, MPEG2 1080p DP x 4 - Up to 3840x2160 CRT x 1 (13 pin Header)- Up to 2048 x 1536 |

| Number of display | 4 (maximum) |

| Supported Technologies | Optimus, GeForce Experence, TXAA, GPU Boost 2.0, PhysX, CUDA, FXAA, OpenCL, Direct Compute, PureVideo HD, HDCP, 3D Vision, OpenGL |

| Board Information | Board Dimensions: 95.89 mm x 90.17 mm Stack Direction: UP (One way) Support Form Factor: StackPC and PCIe/104 |

Thermal Measurement

PERFECTRON provides real lab testing figures to show how CPU performance is with each tailor made thermal kits as important references and design guide for system engineers. For system integration, the crucial challenge is the operation performance under high temperature, thus PERFECTRON conducts long time experiments to make sure the superior testing result for all critical missions. By revealing temperature at processor T junction, processor die and heat sink, PERFECTRON is able to analyse the thermal solution we designed achieves maximum efficacy and observe CPU performance. The high temperature testing takes 5 hours which at each temperature point we burn in F1 for one hour, from -40 to +85°C.

- Rugged COTS computer with Intel®3rd generation Core- i7 processor

- NVIDIA®GPU GT730M supports CUDA 384 independent displays by 4 x DP

- Modular rugged chassis with stackable PCIe/104 I/O card expansion

- 28V DC MIL-STD-1275/704/DO-160 Power supply with Voltage transient protections

- Design for reliability under demanding MIL-STD-810G/DO-160/MIL-461F Thermal Shock, Vibration, Humidity/EMI/EMC conditions

- Rugged IP67 aluminum chassis with MIL-DTL-38999 connectors

- Military grade M12 X-coded connector

- Operating temperature range : -40°C to 85°C

When StackPC meets ATR Structure…

ATR, which stands for Air Transport Rack, is a universal standard that determines the dimension and function of a rugged system especially dedicated to avionics/aerospace applications.

PERFECTRON’s Unique Solution

While usual ATR structure incorporates PCI, VPX, and VME based form factors, PERFECTRON’s OXY5535B-30 Conduction cooled ATR is powered by PCIe104 small form factor modules. PCIe104 – StackPC architecture provides even more flexibility in designing rugged COTS computers. Also known as ARINC, the concept has been used universally for not only aviation purpose but also vehicles with wheels and tracks.

The Power of Conduction Cooling

PERFECTRON, being the master of thermal design, has once again achieved fanless design through conduction cooling method. With each layer comes a heat plate to touch directly the heated parts, the thermal performance is of the highest level. The top side, which is designated as the customized I/O interface, is equipped with water/dust proof MIL-STD M12 connectors (enhanced D38999 by request).

CALMARK Wedge-Lok

To ensure maximum reliability in rugged, heavy shock, and high vibration terrains, Wedge-loks from CALMARK can provide equally satisfying results. With 5 segments, shifted design, Wedge loks also help to transfer the heat and ensure best conductivity of heat load. The multi-segment design highlights on its ability to withstand massive vibration and shock, providing even higher sustainability through the torque-limiting design.

Conductive Cooling Modules for Low/middle/high Power

A solid material that can effectively conduct the heat is used to move the heat to the system enclosure and dissipated to the external surroundings. The machined copper cooling plates matching the component layout are placed between each layer; heat is carried away to the edges where a wedge lok mechanism secures inside the chassis, coming up with a thermal interface.

Conduction Cooled Chassis Platform up to 10 Slots

PERFECTRON’s ATR solution comes with an all-in-one design enclosure; each slot can securely fit a CALMARK wedge-lok, and each layer comes with a firmly attached, directly touched copper heat plate to complete a effectively cooled interior. What makes conduction cooling method so practical is that it is without moving parts, therefore suitable for high altitude and underwater applications.